-

LED Neon Flex / Top Bend (Pro/CCT/RGB/Digital/DMX/3D)

-

LED Neon Flex / Side Bend (Pro/CCT/RGB/Digital/DMX/360°)

-

COB Flex Strip / Single Color (Pro/Efficiency/CC/Slim/FreeCut/SideView)

-

COB Flex Strip (CCT/RGB/RGBW/RGBCCT/Digital/DMX)

-

COB Flex Strip / Neon Structure (IP20/IP67)

-

Flex LED Wall Washer (New)

-

Aluminum Profile (Surface Mounted/Pendant/Stairs)

-

Aluminum Profile (Recessed/Embedded/Inground)

-

Aluminum Profile (Return Groove/Ceiling))

-

Aluminum Profile ( Magnetic/Ring/Module)

-

High Efficiency LED Strip (200lm/160lm/130lm/Meter)

-

2835 Series LED Strip (Hot)

-

2110/2216 Series LED Strip

-

Twin Color LED Strip (New)

-

RGB/RGBW/RGBCCT LED Strip(New)

-

Full Spectrum LED Strip (New)

-

Constant Current Led Strip (New)

-

High Voltage 110/220V LED Strip

-

5050 Series LED Strip

-

3014 Series LED Strip

-

Accessories/Controller/Driver

-

LED Grow Light (New)

-

LED Module

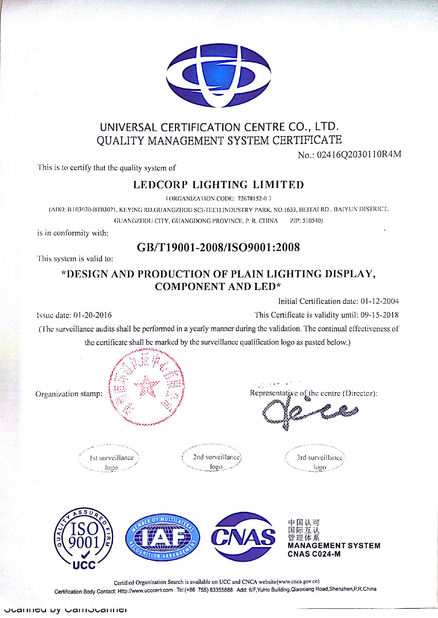

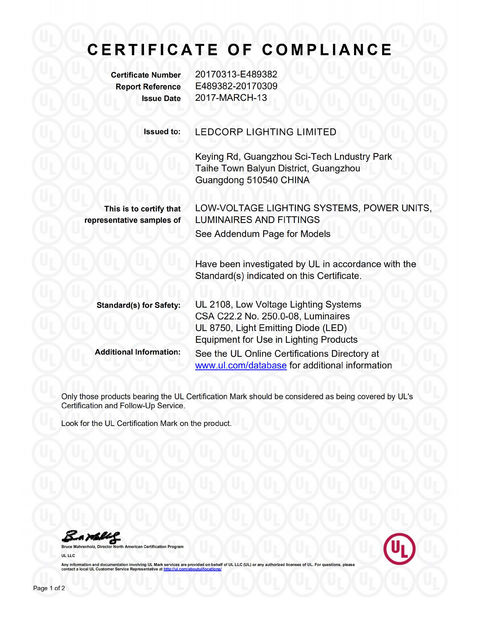

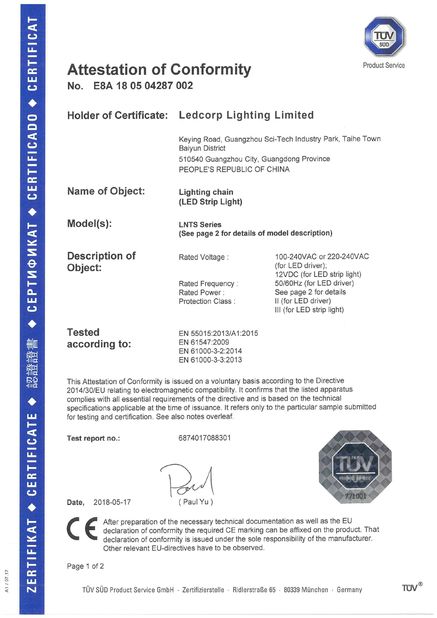

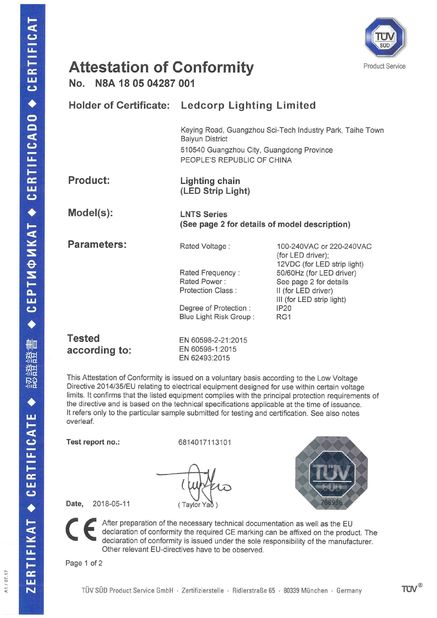

Certificates

-

ISO9001:2008

-

ISO9001:2015

-

UL

-

UL

-

TUV-CE EMC

-

TUV-CE EMC

-

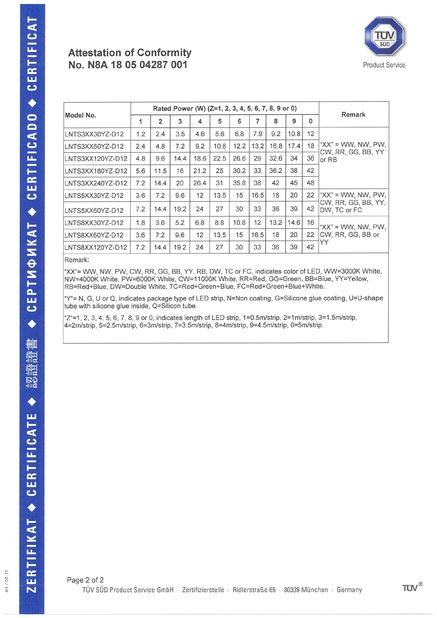

TUV-CE LCD

-

TUV-CE LCD

-

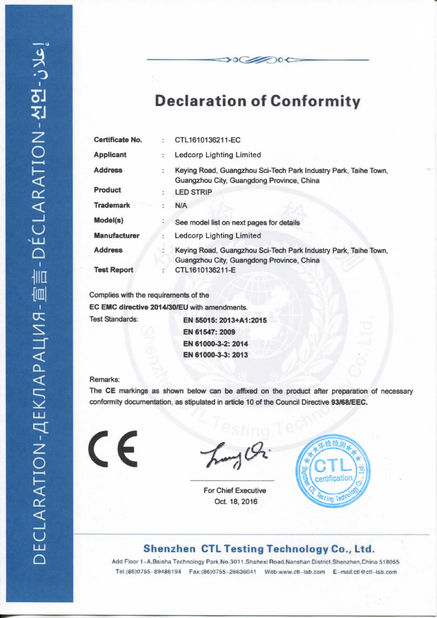

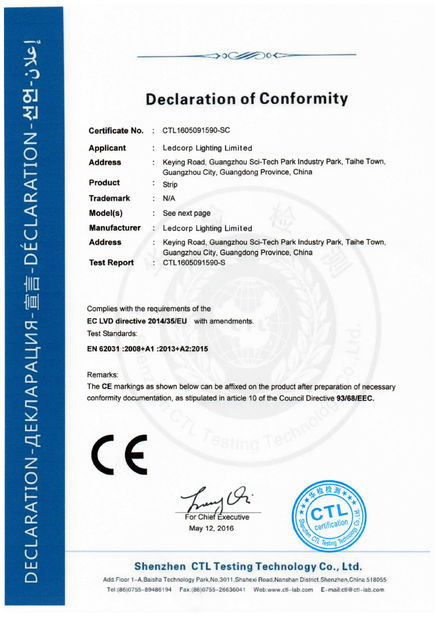

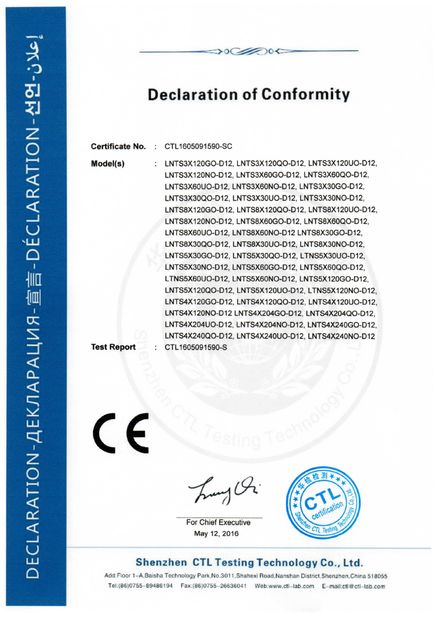

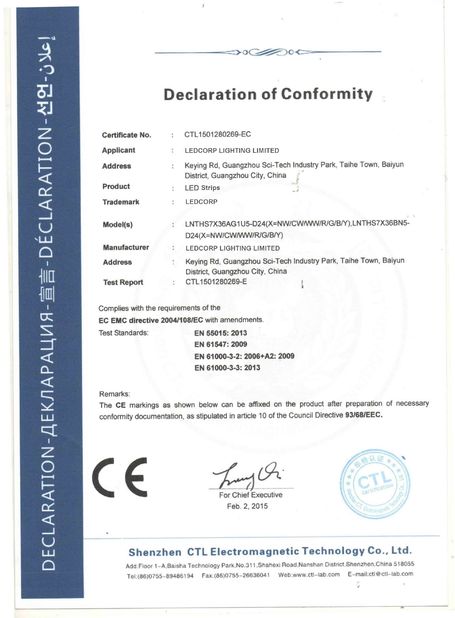

CE

-

CE

-

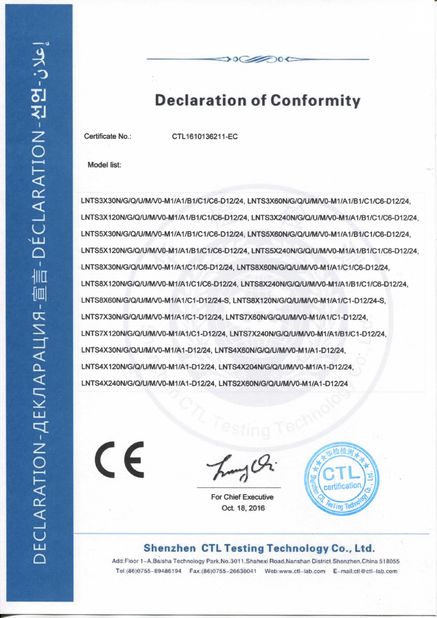

CE EMC

-

CE EMC

-

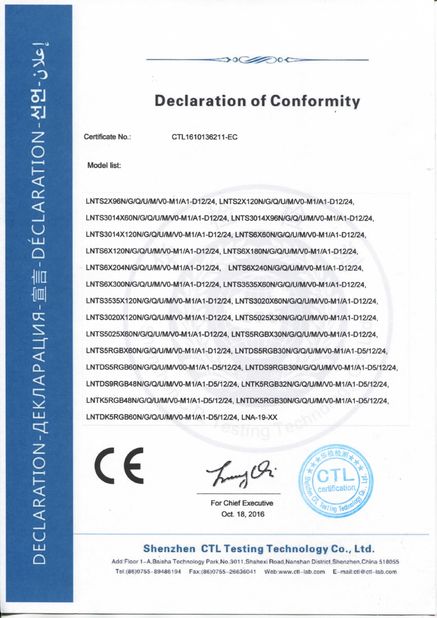

CE EMC

-

CE LVD

-

CE LVD

-

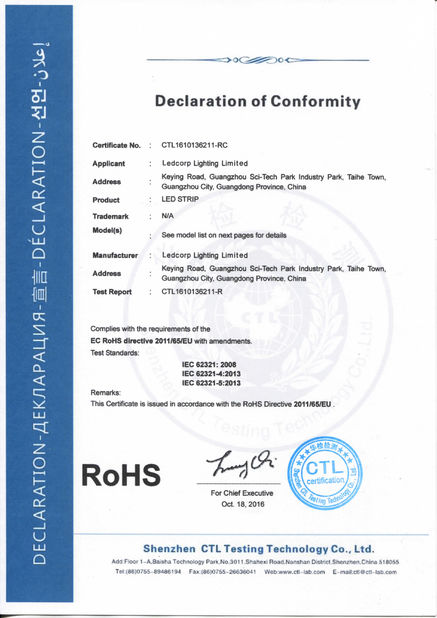

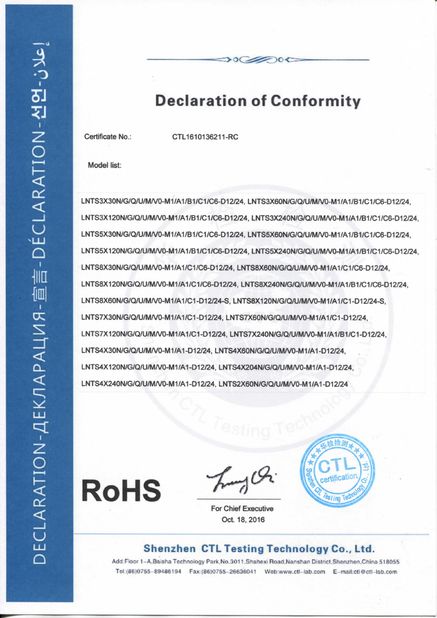

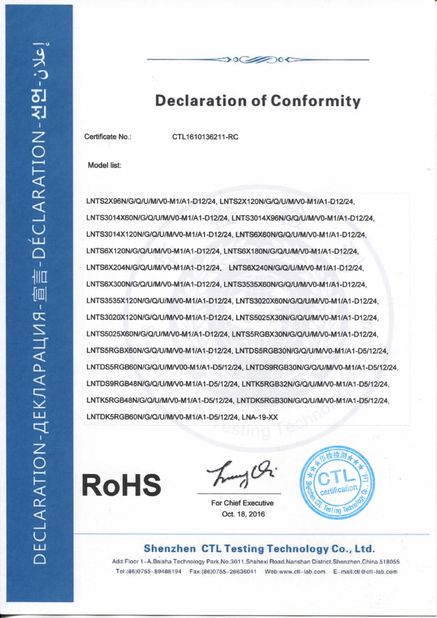

RoHS

-

RoHS

-

RoHS

-

CE

-

CE

QC Profile

Incoming Raw Material Inspection and 6 steps inspection during production

1. Led photoelectric parameter test

2. First sample inspection before mass production

3. Machine inspection after reflow soldering (half- finished products).

4. Aging test for 12- 24 hours (100%)

5. 100% test of opelectronic parameters (finished products)

6. Random inspection (10-20%) before shipment

1. SMD LED capsulation,control of brightness,color temperature(Bins),photoelectricity test ( 1st test ).

![]()

![]()

2. SMD attached on PCB with Automatic machine, samples by manual work.

![]()

![]()

![]()

![]()

3.Bake to dry.

![]()

4.Light up test ( 2nd test ) after baking.

![]()

![]()

5.Soldering each 50 cm PCB to 5 meters,wires soldering by manual work.

![]()

![]()

![]()

6. Aging test ( 3rd test ) at least 8 hours.

![]()

7.Separate the led strips to each reel ( 5meters )

![]()

8. Paste 3M tape onto the led strips.

![]()

9. Testing ( 4th test ) before packaging for IP20 led strips.

![]()

10. Repair work when discover drawback.

![]()

11. Led strips IP66 with empty tube production and test ( 5th test ).

![]()

![]()

![]()

12. Led strips IP65 with dropper glue and test ( 5th test ).

![]()

![]()

![]()

Qualty control process:

![]()